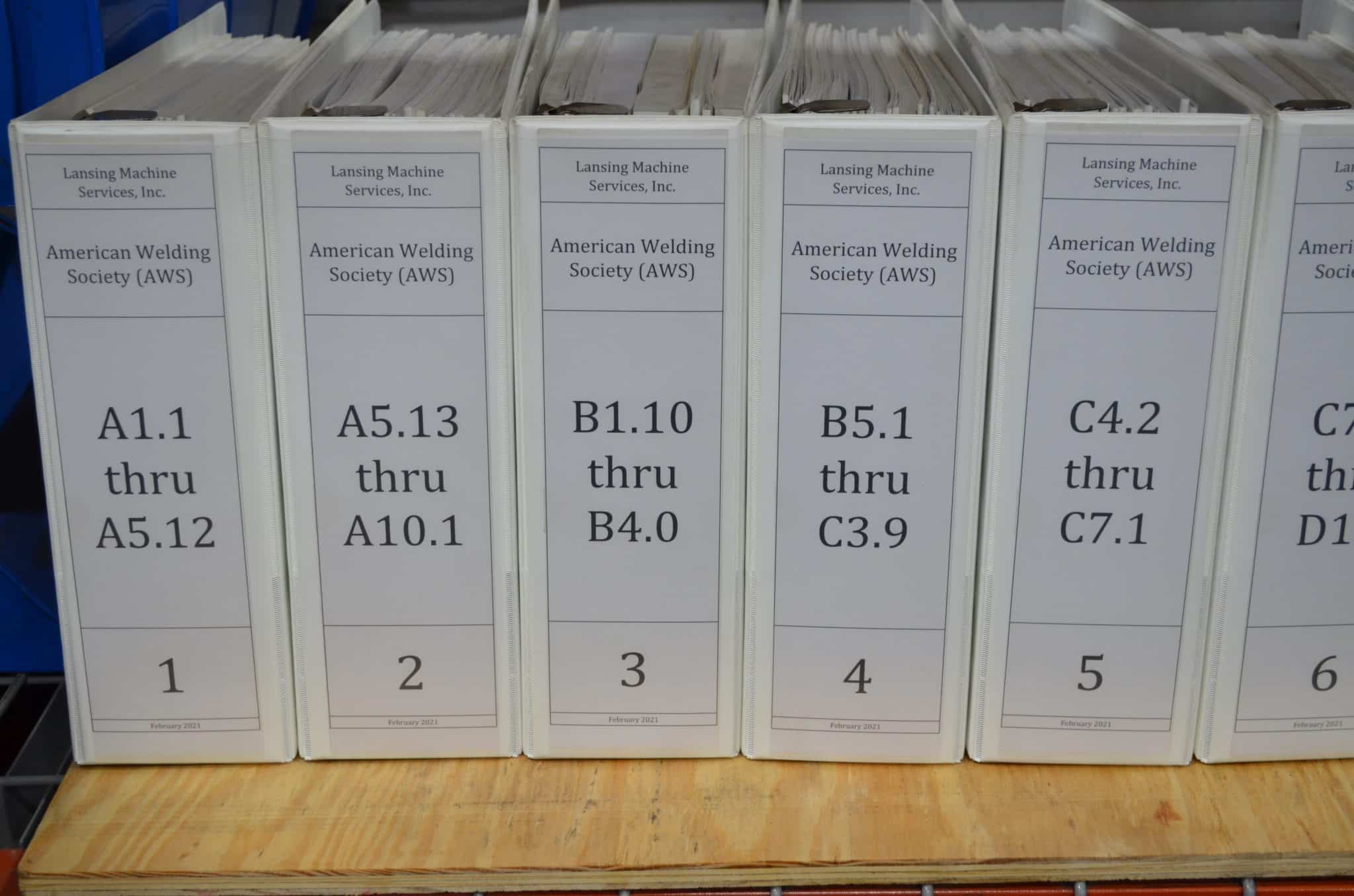

Description

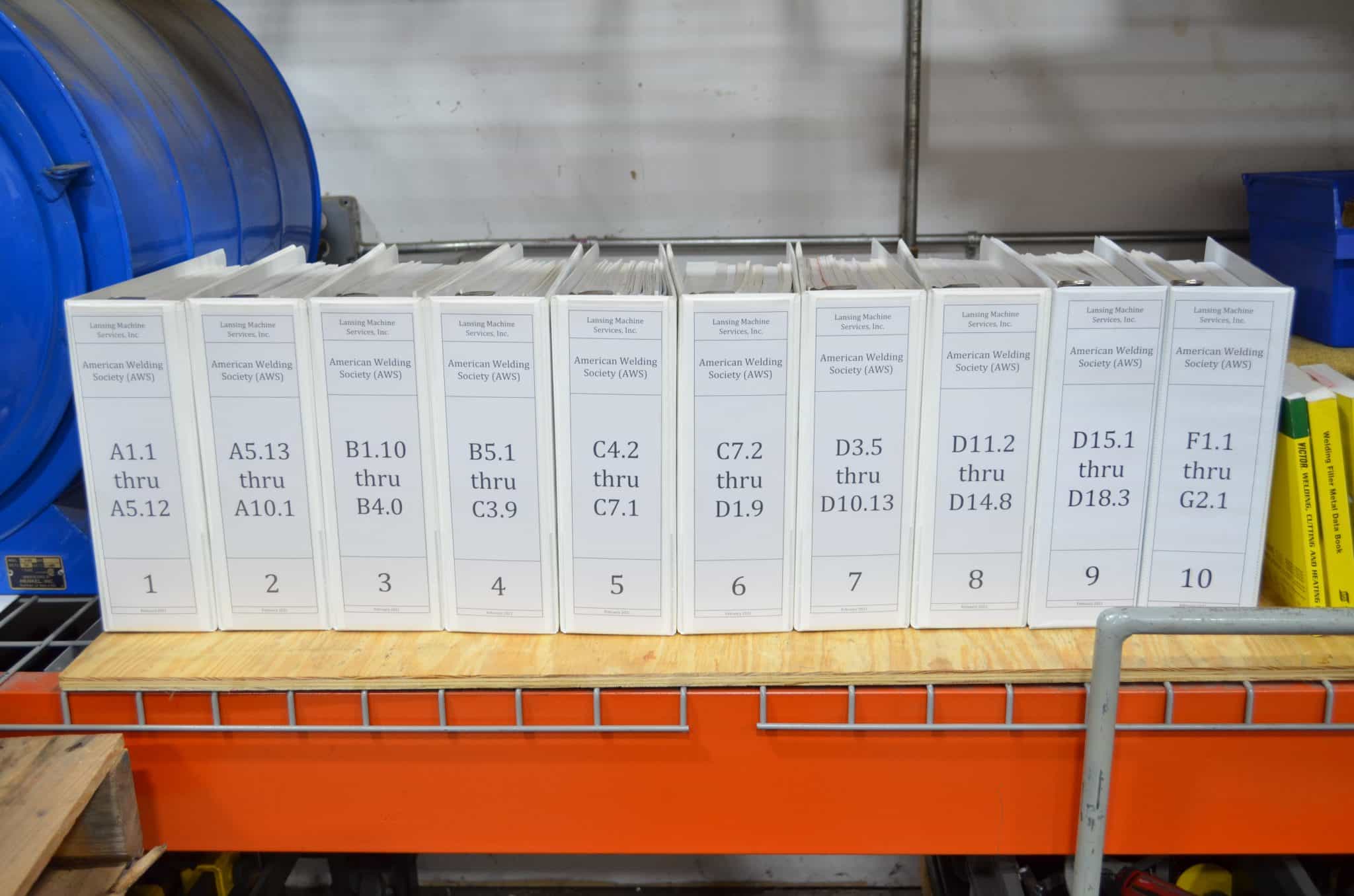

160 AWS Standards as listed below

| BINDER # | REFERENCE # | REVISION DATE | DESCRIPTION |

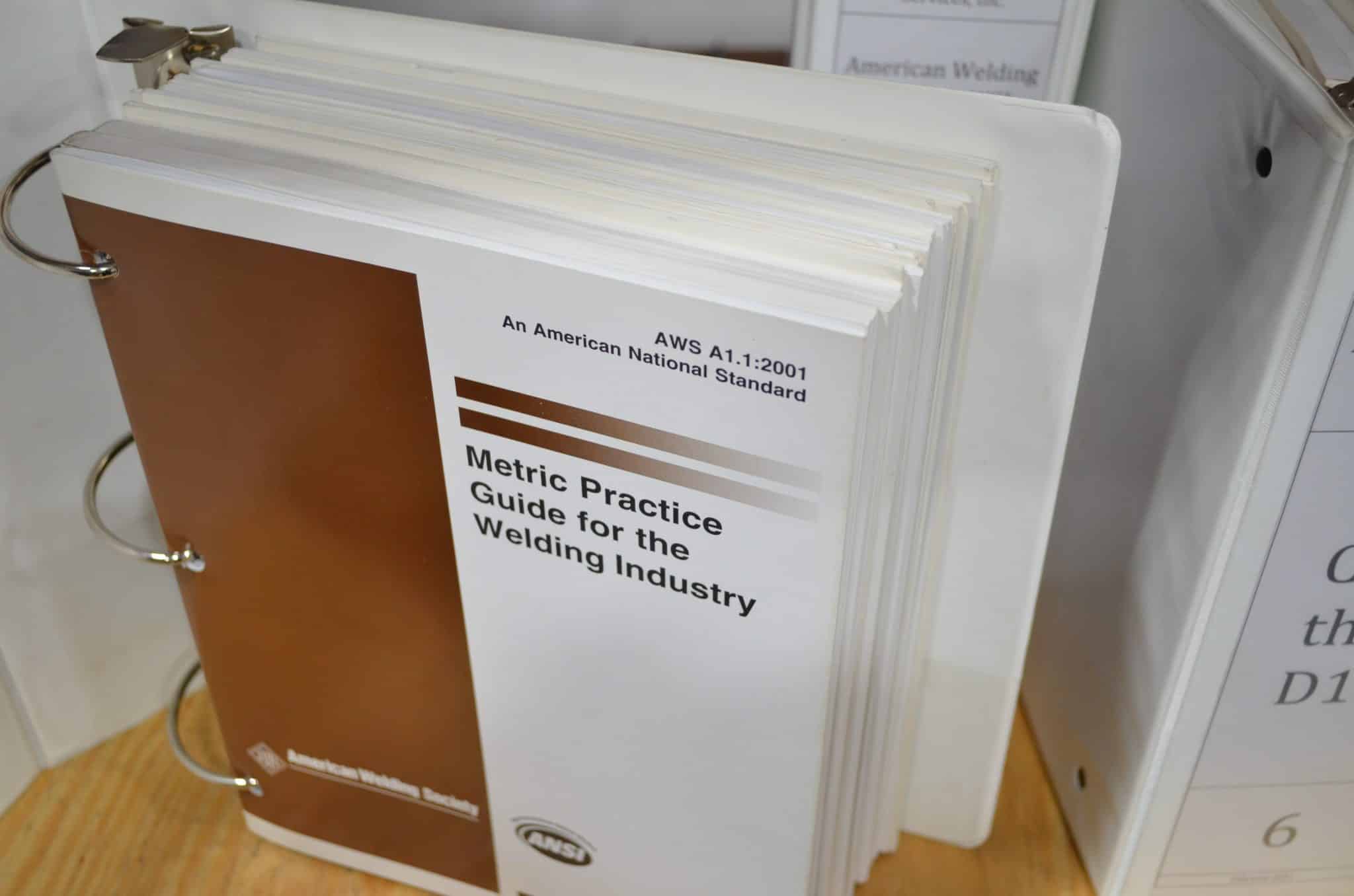

| 1 | A1.1:2001 | 2001 | METRIC PRACTICE GUIDE FOR THE WELDING INDUSTRY |

| 1 | A2.4:2007 | 2007 | Standard Symbols for Welding, Brazing, and Nondestructive Examination |

| 1 | A3.0:2001 | 2001 | STANDARD WELDING TERMS AND DEFINITIONS INCLUDING TERMS FOR ADHESIVE BONDING, BRAZING, SOLDERING, THERMAL CUTTING, AND THERMAL SPRAYING |

| 1 | A4.2M:2006 | 2006 | (ISO 8249:2000 MOD) STANDARD PROCEDURES FOR CALIBRATING MAGNETIC INSTRUMENTS TO MEASURE THE DELTA FERRITE CONTENT OF AUSTENITIC AND DUPLEX FERRITIC-AUSTENITIC STAINLESS STEEL WELD METAL |

| 1 | A4.3-93 | R2006 | STANDARD METHODS FOR DETERMINATION OF THE DIFFUSIBLE HYDROGEN CONTENT OF MARTENSITIC, BAINITIC, AND FERRITIC STEEL WELD METAL PRODUCED BY ARC WELDING |

| 1 | A4.4M:2001 | 2001 | STANDARD PROCEDURES FOR DETERMINATION OF MOISTURE CONTENT OF WELDING FLUXES AND WELDING ELECTRODE FLUX COVERINGS |

| 1 | A5.01M/A5.01:2008 | 2008 | PROCUREMENT GUIDELINES FOR CONSUMABLES – WELDING AND ALLIED PROCESSES – FLUX AND GAS SHIELDED ELECTRICAL WELDING PROCESSES |

| 1 | A5.02/A5.02M:2007 | 2007 | SPECIFICATION FOR FILLER METAL STANDARD SIZES PACKAGING AND PHYSICAL ATTRIBUTES |

| 1 | A5.1/A5.1M:2004 | 2004 | SPECIFICATION FOR CARBON STEEL ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.2/A5.2M:2007 | 2007 | SPECIFICATION FOR CARBON AND LOW-ALLOY STEEL RODS FOR OXYFUEL GAS WELDING |

| 1 | A5.3/A5.3M:1999 | R2007 | SPECIFICATION FOR ALUMINUM AND ALIMINUM – ALLOY ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.4/A5.4M:2006 | 2006 | SPECIFICATION FOR STAINLESS STEEL ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.5/A5.5M:2006 | 2006 | SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.6/A5.6M:2008 | 2008 | SPECIFICATION FOR COPPER AND COPPER-ALLOY ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.7/A5.7M:2007 | 2007 | SPECIFICATION FOR COPPER AND COPPER-ALLOY BARE WELDING RODS AND ELECTRODES |

| 1 | A5.8/A5.8M:2004 | 2004 | SPECIFICATION FOR FILLER METALS FOR BRAZING AND BRAZE WELDING |

| 1 | A5.9/A5.9M:2006 | 2006 | SPECIFICATION FOR BARE STAINLESS STEEL WELDING ELECTRODES AND RODS |

| 1 | A5.10/A5.10M:1999 | R2007 | SPECIFICATION FOR BARE ALUMINUM AND ALUMINUM-ALLOY WELDING ELECTRODES AND RODS |

| 1 | A5.11/A5.11M:2005 | 2005 | SPECIFICATION FOR NICKEL AND NICKEL-ALLOY WELDING ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 1 | A5.12/A5.12M-98 | R2007 | SPECIFICATION FOR TUNGSTEN AND TUNGSTEN-ALLOY ELECTRODES FOR ARC WEDLING AND CUTTING |

| 1 | A5.13:2000 | 200 | SPECIFICATION FOR SURFACING ELECTRODES FOR SHIELDED METAL ARC WELDING |

| 2 | A5.14/A5.14M:2009 | 2009 | SPECIFICATION FOR NICKEL AND NICKEL-ALLOY BARE WELDING ELECTRODES AND RODS |

| 2 | A5.15-90 | R2006 | SPECIFICATION FOR WELDING ELECTRODES AND RODS FOR CAST IRON |

| 2 | A5.16/A5.16M:2007 | 2007 | SPECIFICATION FOR TITANIUM AND TITANIUM-ALLOY WELDING ELECTRODES AND RODS |

| 2 | A5.17/A5.17M-97 | R2007 | SPECIFICATION FOR CARBON STEEL ELECTRODES AND FLUXES FOR SUBMERGED ARC WELDING |

| 2 | A5.18/A5.18M:2005 | 2005 | SPECIFICATION FOR CARBON STEEL ELECTRODES AND RODS FOR GAS SHEILDED ARC WELDING |

| 2 | A5.19-92 | R2006 | SPECIFICATION FOR MAGNESIUM ALLOY WELDING ELECTRODES AND RODS |

| 2 | A5.20/A5.20M:2005 | 2005 | SPECIFICATION FOR CARBON STEEL ELECTRODES FOR FLUX CORED ARC WELDING |

| 2 | A5.21:2001 | 2001 | SPECIFICATION FOR BARE ELECTRODES AND RODS FOR SURFACING |

| 2 | A5.22-95 | R2005 | SPECIFICATION FOR STAINLESS STEEL ELECTRODES FOR FLUX CORED ARC WELDING AND STAINLESS STEEL FLUX CORED RODS FOR GAS TUNGSTEN ARC WELDING |

| 2 | A5.22-95:2010 | 2010 | SPECIFICATION FOR STAINLESS STEEL ELECTRODES FOR FLUX CORED ARC WELDING AND STAINLESS STEEL FLUX CORED RODS FOR GAS TUNGSTEN ARC WELDING |

| 2 | A5.23/A5.23M:2007 | 2007 | SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES AND FLUXES FOR SUMERGED ARC WELDING |

| 2 | A5.24/A5.24M:2005 | 2005 | SPECIFICATION FOR ZIRCONIUM AND ZIRCONIUM-ALLOY WELDING ELECTRODES AND RODS |

| 2 | A5.25/A5.25M-97R | 1997 | SPECIFICATION FOR CARBON AND LOW-ALLOY STEEL ELECTRODES AND FLUXES FOR ELECTROSLAG WELDING |

| 2 | A5.26/A5.26M-97R | 1997 | SPECIFICATION FOR CARBON AND LOW-ALLOY STEEL ELECTRODES FOR ELECTROGAS WELDING |

| 2 | A5.28/A5.28M:2005 | 2005 | SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES AND RODS FOR GAS SHIELDED ARC WELDING |

| 2 | A5.29/A5.29M:2005 | 2005 | SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES FOR FLUX CORED ARC WELDING |

| 2 | A5.29/A5.29M:2010 | 2010 | SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES FOR FLUX CORED ARC WELDING |

| 2 | A5.30-A5.30M:2007 | 2007 | SPECIFICATION FOR CONSUMABLE INSERTS |

| 2 | A5.31-92R | 1992 | SPECIFICATION FOR FLUXES FOR BRAZING AND BRAZE WELDING |

| 2 | A5.32/A5.32M-97 | R2007 | SPECIFICATION FOR WELDING SHIELDING GASES |

| 2 | A5.34/A5.34M:2007 | 2007 | SPECIFICATION FOR NICKEL-ALLOY ELECTRODES FOR FLUX CORED ARC WELDING |

| 2 | A10.1M:2007 | 2007 | Specification for Calibration and Performance Testing of Secondary Current Sensing Coils and Weld Current Monitors used in Single-Phase AC Resistance Welding |

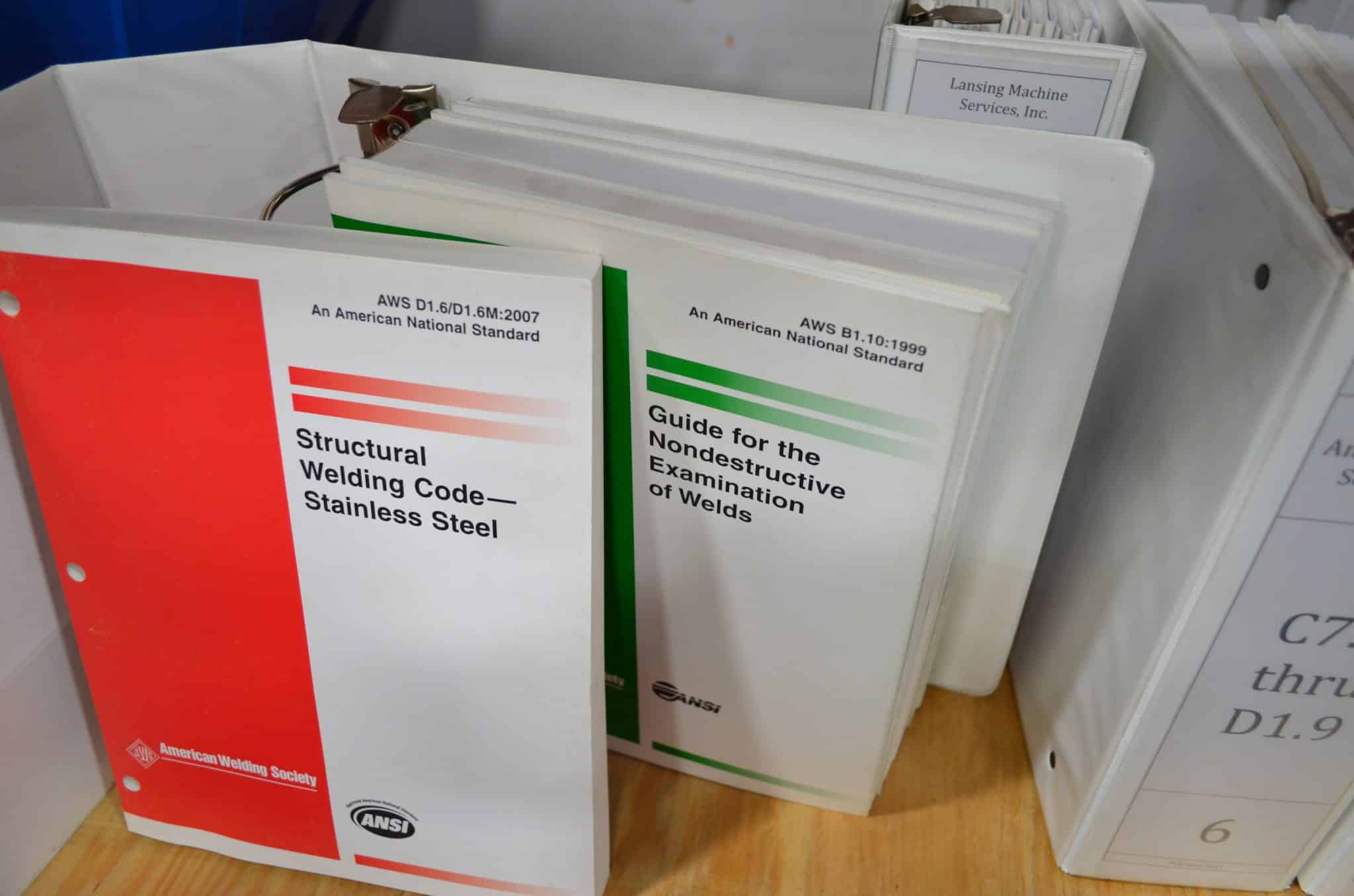

| 3 | B1.10:1999 | 1999 | GUIDE FOR THE NONDESTRUCTIVE EXAMINATION OF WELDS |

| 3 | B1.10M/B1.10:2009 | 2009 | GUIDE FOR THE NONDESTRUCTIVE EXAMINATION OF WELDS |

| 3 | B1.11:2000 | 2000 | GUIDE FOR THE VISUAL EXAMINATION OF WELDS |

| 3 | B2.1:2005 | 2005 | SPECIFICATION FOR WELDING PROCEDURE AND PERFORMACE QUALIFICATION |

| 3 | B2.1/B2.1M:2009 | 2009 | SPECIFICATION FOR WELDING PROCEDURE AND PERFORMACE QUALIFICATION |

| 3 | B2.2-91 | 1991 | STANDARD FOR BRAZING PROCEDURE AND PERFORMANCE QUALIFICATION |

| 3 | B2.3/B2.3M:2008 | 2008 | SPECIFICATION FOR SOLDERING PROCEDURE AND PERFORMANCE QUALIFICATION |

| 3 | B2.4:2006 | 2006 | SPECIFICATION FOR WELDING PROCEDURE AND PERFORMANCE QUALIFICATION THERMOPLASTICS |

| 3 | B4.0:2007 | 2007 | STANDARD METHODS FOR MECHANICAL TESTING OF WELDS |

| 4 | B5.1:2003 | 2003 | SPECIFICATION FOR THE QUALIFICATION OF WELDING INSPECTORS |

| 4 | B5.2:2001 | 2001 | SPECIFICATION FOR THE QUALIFICATION OF WELDING INSPECTOR SPECIALISTS AND WELDING INSPECTOR ASSISTANTS |

| 4 | B5.4:2005 | 2005 | SPECIFICATION FOR THE QUALIFICATION OF WELDER TEST FACILITIES |

| 4 | B5.5:2000 | 2000 | SPECIFICATION FOR THE QUALIFICATION OF WELDING EDUCATORS |

| 4 | B5.9:2006 | 2006 | SPECIFICATION FOR THE QUALIFICATION OF WELDING SUPERVISORS |

| 4 | B5.14:2002 | 2002 | SPECIFICATION FOR THE QUALIFICATION OF WELDING SALES REPRESENTATIVES |

| 4 | B5.15:2003-AMD1 | 2003 | SPECIFICATION FOR THE QUALIFICATION OF RADIOGRAPHIC INTERPRETERS |

| 4 | B5.15:2010 | 2010 | SPECIFICATION FOR THE QUALIFICATION OF RADIOGRAPHIC INTERPRETERS |

| 4 | B5.16:2006 | 2006 | SPECIFICATION FOR THE QUALIFICATION OF WELDING ENGINEERS |

| 4 | B5.17:2008 | 2008 | SPECIFICATION FOR THE QUALIFICATION OF WELDING FSBRICATORS |

| 4 | C1.1M/C1.1:2000 | R2006 | RECOMMENDED PRACTICES FOR RESISTANCE WELDING |

| 4 | C1.4M/C1.4:2009 | 2009 | SPECIFICATION FOR RESISTANCE WELDING OF CARBON AND LOW-ALLOY STEELS |

| 4 | C1.5:2009 | 2009 | Specification for the Qualification of Resistance Welding Technicians |

| 4 | C2.16/C2.16M:2002 | 2002 | GUIDE FOR THERMAL-SPRAY OPERATOR QUALIFICATION |

| 4 | C2.18-93R | 1993 | GUIDE FOR THE PROTECTION OF STEEL WITH THERMAL SPRAYED COATINGS OF ALUMINUM AND ZINC AND THEIR ALLOYS AND COMPOSITES |

| 4 | C2.20/C2.20M:2002 | 2002 | SPECIFICATION FOR THERMAL SPRAYING ZINC ANODES ON STEEL REINFORCED CONCRETE |

| 4 | C2.21M/C2.21:2003 | 2003 | SPECIFICATION FOR THERMAL SPRAY EQUIPMENT ACCEPTANCE INSPECTION |

| 4 | C2.23M/C2.23:2003 | 2003 | SPECIFICATION FOR THE APPLICATION OF THERMAL SPRAY COATINGS (METALLIZING) OF ALUMINUM, ZINC, AND THEIR ALLOYS AND COMPOSITES FOR THE CORROSION PROTECTION OF STEEL |

| 4 | C2.25/C2.25M:2002 | 2002 | SPECIFICATION FOR THERMAL SPRAY FEEDSTOCK – SOLID AND COMPOSITE WIRE AND CERAMIC RODS |

| 4 | C3.2M/C3.2:2008 | 2008 | Standard Method for Evaluating the Strength of Brazed Joints |

| 4 | C3.3:2008 | 2008 | Recommended Practices for the Design, Manufacture, and Examination of Critical Brazed Components |

| 4 | C3.4M/C3.4:2007 | 2007 | SPECIFICATION FOR TORCH BRAZING |

| 4 | C3.5M/C3.5:2007 | 2007 | SPECIFICATION FOR INDUCTION BRAZING |

| 4 | C3.6M/C3.6:2008 | 2008 | SPECIFICATION FOR FURNACE BRAZING |

| 4 | C3.7/C3.7M:2005 | 2005 | SPECIFICATION FOR ALUMINIUM BRAZING |

| 4 | C3.8M/C3.8:2005 | 2005 | SPECIFICATION FOR THE ULTRASONIC EXAMINATION OF BRAZED JOINTS |

| 4 | C3.9M/C3.9:2009 | 2009 | Specification for Resistance Brazing |

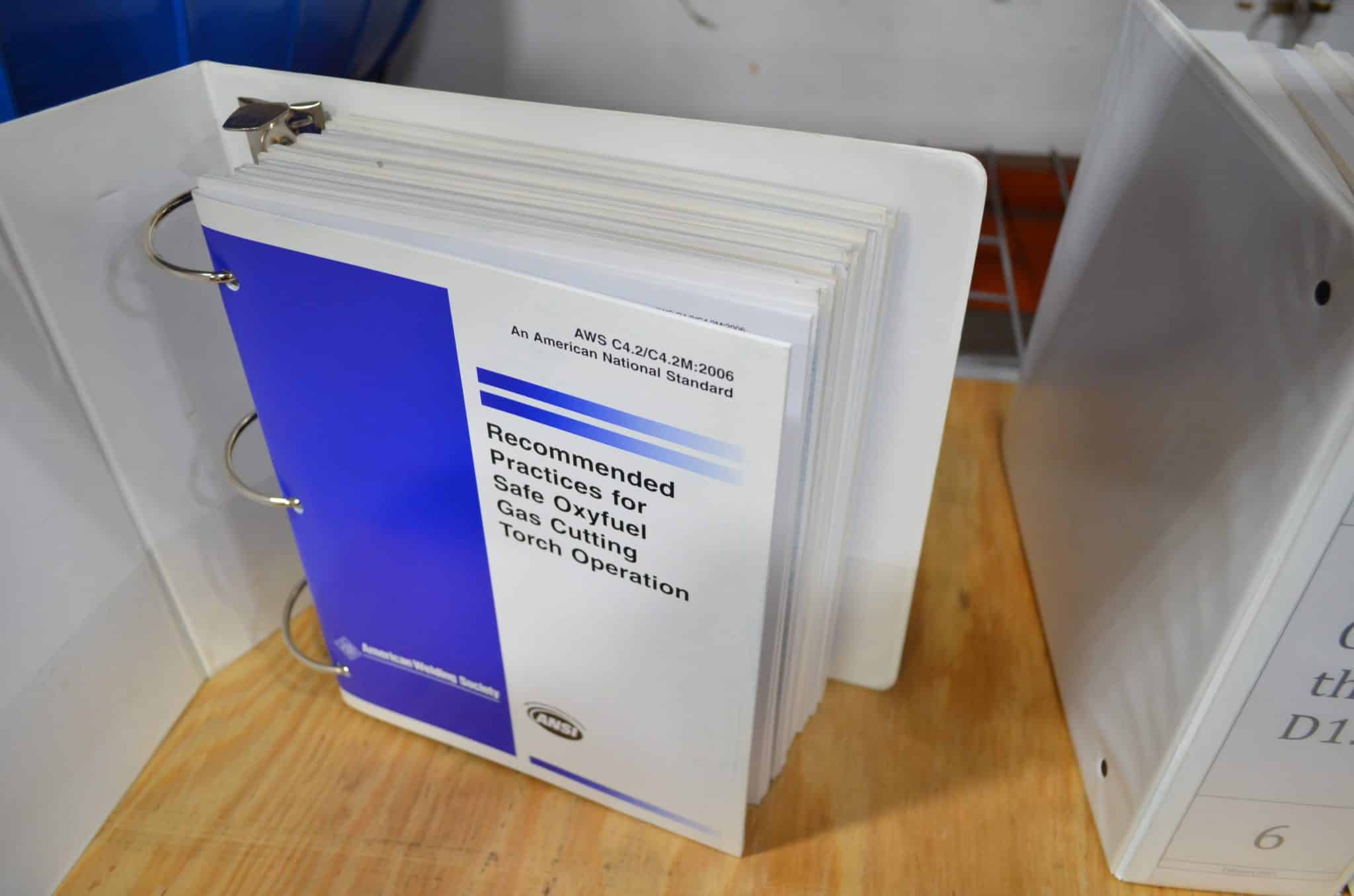

| 5 | C4.2/C4.2M:2006 | 2006 | Recommended Practices for Safe Oxyfuel Gas Cutting Torch Operation |

| 5 | C4.2/C4.2M:2009 | 2009 | Recommended Practices for Safe Oxyfuel Gas Cutting Torch Operation |

| 5 | C4.3/C4.3M:2007 | 2007 | RECOMMENDED PRACTICES FOR SAFE AND OXYFUEL GAS HEATING TORCH OPERATION |

| 5 | C4.4/C4.4M:2007 | 2007 | RECOMMENDED PRACTICES FOR HEAT SHAPING AND STRAIGHTENING WITH OXYFUEL GAS HEATING TORCHES |

| 5 | C4.5M:2006 | 2006 | UNIFORM DESIGNATION SYSTEM FOR OXYFUEL NOZZLES |

| 5 | C4.6M:2006 | 2006 | (ISO 9013:2002 IDT) THERMAL CUTTING – CLASSIFICATION OF THERMAL CUTS – GEOMETRIC PRODUCT SPECIFICATION AND QUALITY TOLERANCES |

| 5 | C5.1-73 | 1973 | RECOMMENDED PRACTICES FOR PLASMA-ARC WELDING |

| 5 | C5.2:2001 | 2001 | RECOMMENDED PRACTICES FOR PLASMA ARC CUTTING AND GOUGING |

| 5 | C5.3:2000 | 2000 | RECOMMENDED PRACTICES FOR AIR CARBON ARC GOUGING AND CUTTING |

| 5 | C5.4-93 | 1993 | RECOMMENDED PRACTICES FOR STUD WELDING |

| 5 | C5.5/C5.5M:2003 | 2003 | RECOMMENDED PRACTICES FOR GAS TUNGSTEN ARC WELDING |

| 5 | C5.6-89R | 1989 | RECOMMENDED PRACTICES FOR GAS METAL ARC WELDING |

| 5 | C5.7:2000 | R2006 | RECOMMENDED PRACTICES FOR ELECTROGAS WELDING |

| 5 | C5.10/C5.10M:2003 | 2003 | RECOMMENDED PRACTICES FOR SHIELDING GASES FOR WELDING AND CUTTING |

| 5 | C6.1-89R | 1989 | RECOMMENDED PRACTICES FOR FRICTION WELDING |

| 5 | C6.2/C6.2M:2006 | 2006 | SPECIFICATION FOR FRICTION WELDING OF METALS |

| 5 | C7.1M/C7.1:2004 | 2004 | RECOMMENDED PRACTICES FOR ELECTRON BEAM WELDING |

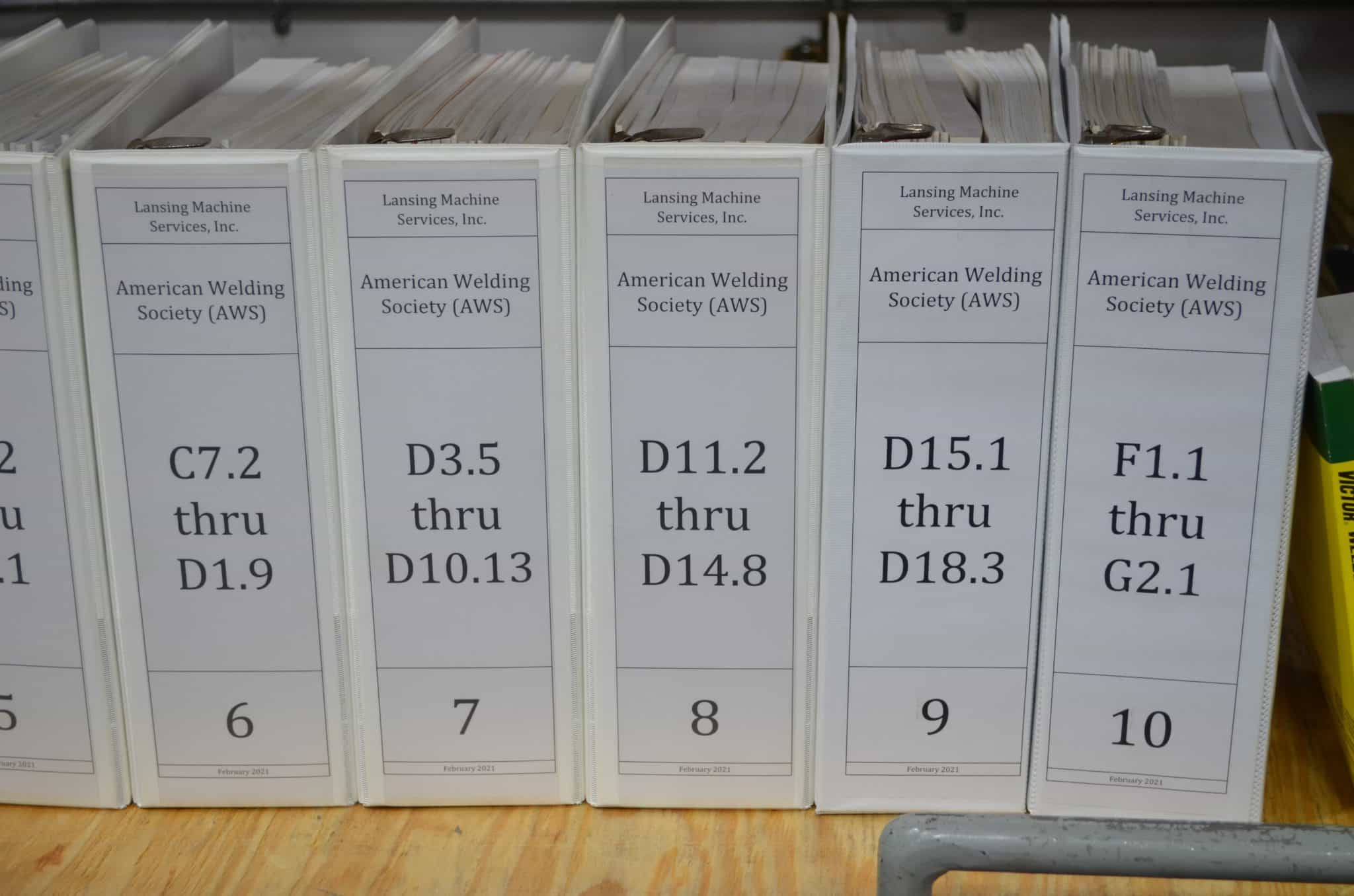

| 6 | C7.2:1998 | 1998 | RECOMMENDED PRACTICES FOR LASER BEAM WELDING, CUTTING, AND DRILLING |

| 6 | C7.3:1999R | 1999 | PROCESS SPECIFICATION FOR ELECTRON BEAM WELDING |

| 6 | C7.4/C7.4M:2008 | 2008 | Process Specification and Operator Qualification for Laser Beam Welding |

| SHELF | D1.1/D1.1M | 2008 | STRUCTURAL WELDING CODE-STEEL |

| 6 | D1.2/D1.2M:2008 | 2008 | STRUCTURAL WELDING CODE – ALUMINUM |

| 6 | D1.3/D1.3M:2008 | 2008 | STRUCTURAL WELDING CODE-SHEET STEEL |

| 6 | D1.4/D1.4M:2005 | 2005 | STRUCTURAL WELDING CODE – REINFORCING STEEL |

| SHELF | D1.5M/D1.5:2008 | 2008 | BRIDGE WELDING CODE |

| SHELF | D1.6/D1.6M:2007 | 2007 | STRUCTURAL WELDING CODE – STAINLESS STEEL |

| 6 | D1.7/D1.7M:2010 | 2010 | GUIDE FOR STRENGTHENING AND REPAIRING EXISTING STRUCTURES |

| 6 | D1.8/D1.8M:2005 | 2005 | STRUCTURAL WELDING CODE – SEISMIC SUPPLEMENT |

| 6 | D1.8/D1.8M:2009 | 2009 | STRUCTURAL WELDING CODE – SEISMIC SUPPLEMENT |

| 6 | D1.9/D1.9M:2007 | 2007 | STRUCTURAL WELDING CODE – TITANIUM |

| 7 | D3.5-95R | 1993 | GUIDE FOR STEEL HULL WELDING |

| 7 | D3.6M:1999 | 1999 | SPECIFICATION FOR UNDERWATER WELDING |

| 7 | D3.7:2004 | 2004 | GUIDE FOR ALUMINUM HULL WELDING |

| 7 | D8.1M:2007 | 2007 | SPECIFICATION FOR AUTOMOTIVE WELD QUALITY – RESISTANCE SPOT WELDING OF STEEL |

| 7 | D8.6:2005 | 2005 | Standard for Automotive Resistance Spot Welding Electrodes |

| 7 | D8.7M:2005 | 2005 | RECOMMENDED PRACTICES FOR AUTOMATIVE WELD QUALITY – RESISTANCE SPOT WELDING |

| 7 | D8.8M:2007 | 2007 | SPECIFICATION FOR AUTOMOTIVE WELD QUALITY – ARC WELDING OF STEEL |

| 7 | D8.9M:2002 | 2002 | RECOMMENDED PRACTICES FOR TEST METHODS FOR EVALUATING THE RESISTANCE SPOT WELDING BEHAVIOR OF AUTOMOTIVE SHEET STEEL MATERIALS |

| 7 | D8.14M:2008 | 2008 | SPECIFICATION FOR AUTOMOTIVE WELD QUALITY – ARC WELDING ALUMINUM |

| 7 | D9.1M/D9.1:2006 | 2006 | Sheet Metal Welding Code |

| 7 | D10.4-86R | 1986 | RECOMMENDED PRACTICES FOR WELDING AUSTENITIC CHROMIUM – NICKEL STAINLESS STEEL PIPING AND TUBING |

| 7 | D10.6/D10.6M:2000 | 2000 | RECOMMENDED PRACTICES FOR GAS TUNGSTEN ARC WELDING OF TITANIUM PIPING AND TUBING |

| 7 | D10.7M/D10.7:2008 | 2008 | Guide for the Gas Shielded Arc Welding of Aluminum and Aluminum Alloy Pipe |

| 7 | D10.8-96 | 1996 | WELDING OF CHROMIUM – MOLYBDENUM STEEL PIPING AND TUBING |

| 7 | D10.10/D10.10M:1999 | 1999 | RECOMMENDED PRACTICES FOR LOCAL HEATING OF WELDS IN PIPING AND TUBING |

| 7 | D10.11M/D10.11:2007 | 2007 | GUIDE FOR ROOT PASS WELDING OF PIPE WITHOUT BACKING |

| 7 | D10.12M/D10.12:2000 | 2000 | GUIDE FOR WELDING MILD STEEL PIPE |

| 7 | D10.13/D10.13M:2001 | 2001 | RECOMMENDED PRACTICES FOR THE BRAZING OF COPPER TUBING AND FITTINGS FOR MEDICAL GAS SYSTEMS |

| 8 | D10.18M/D10.18:2008 | 2008 | Guide forWelding Ferritic/Austenitic Duplex Stainless Steel Piping and Tubing |

| 8 | D11.2-89 | R2006 | GUIDE FOR WELDING IRON CASTINGS |

| 8 | D14.1/D14.1M:2005 | 2005 | SPECIFICATION FOR WELDING OF INDUSTRIAL AND MILL CRANES AND OTHER MATERIAL HANDLING EQUIPMENT |

| 8 | D14.3/D14.3M:2005 | 2005 | SPECIFICATION FOR WELDING EARTHMOVING, CONSTRUCTION AND AGRICULTURAL EQUIPMENT |

| 8 | D14.4/D14.4M:2005 | 2005 | SPECIFICATION FOR WELDED JOINTS IN MACHINERY AND EQUIPMENT |

| 8 | D14.5-97 | 1997 | SPECIFICATION FOR WELDING OF PRESSES AND PRESS COMPONENTS |

| 8 | D14.6/D14.6M:2005 | 2005 | SPECIFICATION FOR WELDING OF ROTATING ELEMENTS OF EQUIPMENT |

| 8 | D14.7/D14.7M:2005 | 2005 | RECOMMENDED PRACTICES FOR SURFACING AND RECONDITIONING OF INDUSTRIAL MILL ROLLS |

| 8 | D14.8M:2009 | 2009 | STANDARD METHODS FOR THE AVOIDANCE OF COLD CRACKS |

| 9 | D15.1/D15.1M:2007 | 2007 | Railroad Welding Specification for Cars and Locomotives |

| 9 | D15.2:2003 | 2003 | RECOMMENDED PRACTICES FOR THE WELDING OF RAILS AND RELATED RAIL COMPONENTS FOR USE BY RAIL VEHICLES |

| 9 | D16.1M/D16.1:2004 | 2004 | SPECIFICATION FOR ROBOTIC ARC WELDING SAFETY |

| 9 | D16.2M/D16.2:2007 | 2007 | GUIDE FOR COMPONENTS OF ROBOTIC AND AUTOMATIC ARC WELDING INSTALLATIONS |

| 9 | D16.3M/D16/3:2001 | 2001 | RISK ASSESSMENT GUIDE FOR ROBOTIC WELDING |

| 9 | D16.4M/D16.4:2005 | 2005 | SPECIFICATION FOR THE QUALIFICATION OF ROBOTIC ARC WELDING PERSONNEL |

| 9 | D17.1:2001 | 2001 | SPECIFICATION FOR FUSION WELDING FOR AEROSPACE APPLICATIONS |

| 9 | D17.2/D17.2M:2007 | 2007 | Specification for Resistance Welding for Aerospace Applications |

| 9 | D17.3/D17.3M:2010 | 2010 | Specification for FRICTION STIR WELDING OF ALUMINUM ALLOYS for Aerospace Applications |

| 9 | D18.1:1999 | 1999 | SPECIFICATION FOR WELDING OF AUSTENITIC STAINLESS STEEL TUBE AND PIPE SYSTEM IN SANITARY (HYGIENIC) APPLICATIONS |

| 9 | D18.3/D18.3M:2005 | 2005 | Specification for Welding of Tanks, Vessels, and Other Equipment in Sanitary (Hygienic) Applications |

| 10 | F1.1M:2006 | 2006 | METHOD FOR SAMPLING AIRBORNE PARTICULATES GENERATED BY WELDING AND ALLIED PROCESSES |

| 10 | F1.2:2006 | 2006 | LABORATORY METHOD FOR MEASURING FUME GENERATION RATE AND TOTAL FUME EMISSION OF WELDING AND ALLIED PROCESSES |

| 10 | F1.3M:2006 | 2006 | A SAMPLING STRATEGY GUIDE FOR EVALUATING CONTAMINANTS IN THE WELDING ENVIRONMENT |

| 10 | F1.5M:2003 | 2003 | METHODS FOR SAMPLING AND ANALYZING GASES FROM WELDING AND ALLIED PROCESSES |

| 10 | F1.6:2003 | 2003 | GUIDE FOR ESTIMATING WELDING EMISSIONS FOR EPA AND VENTILATION PERMIT REPORTING |

| 10 | F2.3M:2001 | 2001 | SPECIFICATION FOR USE AND PERFORMANCE OF TRANSPARENT WELDING CURTAINS AND SCREENS |

| 10 | F3.2M/F3.2:2001 | 2001 | VENTILATION GUIDE FOR WELD FUME |

| 10 | F4.1:2007 | 2007 | SAFE PRACTICES FOR THE PREPARATION OF CONTAINERS AND PIPING FORWELDING AND CUTTING |

| 10 | G1.1M/G1.1:2006 | 2006 | Guide to Ultrasonic Assembly of Thermoplastics |

| 10 | G1.2M/G1.2:1999 | 1999 | SPECIFICATION FOR STANDARDIZED ULTRASONIC WELDING TEST SPECIMEN FOR THERMOPLASTICS |

| 10 | G1.6:2006 | 2006 | Specification for the Qualification of Plastics Welding Inspectors for Hot Gas, Hot Gas Extrusion, and Heated Tool Butt Thermoplastic Welds |

| 10 | G1.10M:2001 | 2001 | GUIDE FOR THE EVALUATION OF HOT GAS, HOT GAS EXTRUSION, AND HEATEDTOOL BUTT THERMOPLASTIC WELDS |

| 10 | G2.1M/G2.1:2002 | 2002 | GUIDE FOR THE JOINING OF WROUGHT NICKEL-BASED ALLOYS |